|

|

|

|

|

|

|

|

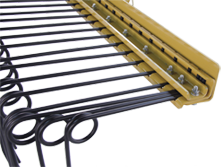

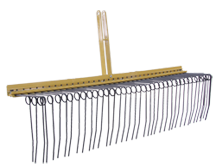

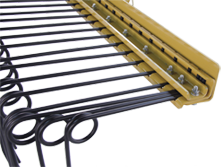

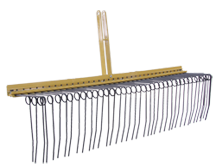

Pine straw rakes connect to the rear of a tractor using a standard 3 point hitch, and you simply use the lift arms to lift them up and lower them in the correct spot to rake up your pine needles. When you lower the rake onto the lawn, the spring action tines give enough resistance to carry pine straw, but not so much as to damage the sod or soil as you are collecting pine needles. The key point of a pine straw rake is the tines, they are considerably weaker than the tines on any landscape rake, so they are more easily broken, users should take care to not put any extra stress on them.

Pine straw rakes are gaining in popularity due to the manufacturing of smaller pine straw balers, which helps homeowners to take full advantage of their pine straw, or to even sell some of them for extra income. In addition to raking pine needles, some people have claimed to use theirs to de thatch lawns, pick up leaves, clean feedlots, gardens, and much more. With the spring action tines on a pine straw rake, it is easy to carry small items such as leaves and of course pine needles over many types of terrains and landscapes. Many homeowners and farmers are using pine straw rakes on their property to provide themselves with a great supply of pine needles, or to even purchase a small pine straw baler and help keep the rest of us in supply.

Out of all of the rakes out there, the rake that sticks out as being the most "owner-friendly" is the Everything Attachments line of pine needle rakes, they are manufactured in Newton, NC where Everything Attachments has been for over 65 years, with over one hundred years of combined experience from top expert employees that have spent the majority of their lives in the farming and tractor industries. It is this knowledge and understanding that has made the Everything Attachments pine straw rake such an innovative piece of equipment. The design of the Everything Attachments pine straw rake is centered around making life easier for the user, starting with basic assembly. Here is a video of Peanut, Everything Attachments' master technician, assembling a pine straw rake, and as you can see the care taken in designing this attachment has led to the ability to ship it via UPS straight to your door at home or work, saving you money on shipping even before the attachment has arrived at its new home. The tines of Pine straw rakes have been a headache for many owners due to a few issues, in order to effectively gather the pine needles, they can not be as stiff as a landscape rake, or the tines will tear up the soil, and these weaker tines have been known to break on other models due to the fact that they are made of a spring-like steel, which is easily damaged by excess heat such as welding which is how they are attached to the implement. The Everything Attachments pine straw rakes use channels and grooves along with a 90 degree bend to hold the tine in place between two u-shaped pieces of steel bolted together which completely eliminates the problem of excess heat on the springy tines. This design allows the tines to maintain their strength, and not be subject to breaking as easily(at the end of 5 months of production there have been no reported broken tines). In the event that one of the tines breaks, changing out the broken tine is as simple as unbolting the top bar, removing the remaining piece of the broken tine, inserting the new tine, and then bolting the bar back on. This process ensures that the tines delicate spring function is maintained and the tine is not weakened by the heat of a welder.